| |

|

|

|

| |

1. |

Base Oils |

|

| |

|

Both domestic as well as imported i.e.SN70/SN100/SN150/SN500 in

group-1 & Group-2, Group-5 & PAO

Heavy alakalid (HA),Pale-2000

Carbon

HCO

Furnance Oil

Transformer Oil

|

|

|

| |

|

|

|

| |

2. |

Bio - Plastics |

|

| |

|

Available as Certified Compostable or BiohybridTM, Cardia resins are

heavy metal free, made with less oil, contain GMO free renewable

plant based material and are US FDA and EU food contact regulatory

requirements compliant. With a lower carbon footprint, Cardia

Bioplastics Compostable and BiohybridTM resins are the quality

sustainable choice!

Cardia Bioplastics Compostable & BiohybridTM Resins

Available in two environmentally friendly options

|

| |

|

1. Cardia Compostable resins

Certified biodegradable & compostable

Made with less oil

Contain GMO free, renewable, plant based material

Can be composted in aerobic, industrial

composting plants

Turned into compost, condition soil for improved

plant growth

Independently verified

Cardia Compostable resins meet international standards for

compostability, including Europes EN 13432, the USAs ASTM D 6400,

Japans GreenPla, Australias AS 4736.

Cardia Compostable resins enable customers to offer fully

compostable packaging and plastic products, with no additional

investment in existing production equipment. Derived from renewable

resources, our products are soft touch, colourable and printable.

Typical Cardia Compostable resin applications include:

Flexible film up to 120 microns

Shopping bags & Carry bags

Bin liners & garden waste bags

Mulch films

Injection moulded products including cutlery & food utensils, ice

cream sticks and closures

We can develop compounds for specific customer needs, as well as offering a base compostable resin range, including:

| Product Name |

Description |

End use |

| Cardia Compostable B-F |

Biodegradable Film and Extrusion Grade |

Masterbatch for flexible film applications |

| Cardia Compostable B-M |

Biodegradable Moulding Grade |

Masterbatch for rigid packaging applications |

|

|

|

| |

|

2. Cardia BiohybridTM resins

Made with less oil & heavy metal free

Contain GMO free, renewable, plant based material

Reduces global warming by sequestering CO2

Lower carbon foot print verified by independent Life

Cycle Assessment

Cost effective alternative to fossil fuel derived

plastic packaging

Recyclable in conventional plastic recycling streams

Cardia BiohybridTM resins are a blend of renewable thermoplastic

materials and traditional polyolefins. BiohybridTM resins allow

manufacturers to embrace sustainable packaging early with existing

equipment, and enable them to immediately increase the renewable

content of their products by up to 50% and reduce their carbon

footprint. Cardia BiohybridTM high performance range is colourable

and printable.

Typical applications include:

Flexible film

Overwrap packaging

Shopping bags & Carry bags

Bin liners & garden waste bags

Blow moulded bottles

Injection moulded products including cutlery & food utensils,

pens and closures

Packaging foams

Cardia Bioplastics can tailor compounds to suit specific customer

applications. The base BiohybridTM resins range includes:

| Product Name |

Description |

End use |

| Cardia BiohybridTM BL-F |

High renewable, blendable Film and Extrusion Grade |

Masterbatch for flexible film applications |

| Cardia BiohybridTM BL-M |

High renewable, blendable Moulding Grade |

Masterbatch for rigid packaging applications |

|

Cardia Bioplastics is an Australian headquartered global developer, manufacturer and marketer of sustainable resins, films, bags and

products derived from renewable resources.

Our range of certified Cardia Compostable and Cardia BiohybridTM bags, products and waste management systems deliver a lower

carbon footprint and are ideal for homes, gardens, businesses and councils.

Cardia Bioplastics, the quality sustainable choice - validated around the world by homes, councils, businesses and leading brands.

|

|

|

| |

|

|

|

| |

3. |

Bitumen |

|

| |

|

|

|

|

| |

|

|

|

| |

4. |

Chemicals & Solvents |

|

|

| |

|

1) Benzene

2) Tolune

3) Resin Binders

4) MEK

5) MGO

|

|

|

| |

5. |

Dearomatized Hydrocarbon Fluids From Shell Global Chemicals

|

|

| |

|

Low odour high flash point

Environmental free

Low HAP

Low VOC

|

|

|

| |

6. |

Carbon Black |

|

|

| |

|

Powder & graunulated

N 220

N 330

N 440

N 550

N 660

N 770 etc.

|

|

|

| |

|

|

|

| |

|

|

|

| |

7. |

Engineering Plastics |

|

|

| |

|

1) SAN

2) ABS

3) Nylon-6 Firestone textile co Ltd-Canada

4) PET

5) PBT

6) Polysterene

7) FKM/PTFE/FEP/PVDF from APS Flouro elstomers USA

8) PVDF

9) PTFE

10) FEP

|

|

|

| |

|

|

|

| |

8. |

Gum Rosin Derivatives |

|

|

|

| |

|

1) Penteasters

2) Glyceroleasters

3) Gum terpentine

|

|

|

| |

|

|

|

| |

9. |

Hydrocarbon Resins C5/C9 |

|

|

| |

|

1) Phenolic Resins |

|

|

| |

|

|

|

| |

10. |

Leather Chemicals From Quimser. S.A. Spain

|

|

| |

|

Drum dye & Fatliquors

Waxes, Binders & resins

Laquers, auxiliraies & Filling Agents

Pigment and anilines etc.

|

|

|

|

| |

11. |

OCP'S for VI Improvers & Lubricant Additives |

|

|

| |

|

1) Calcium Sulphonates

2) Pour point Depressants

3) Sodium Petroleum Sulphonates

4) Lubricants additive packages for automotive and industrial lubricant

packages

5) Lithium Hydraxide

6) ZDDP

7) PIBSA

|

|

|

| |

|

|

|

| |

|

|

|

| |

12. |

Paraffin & Microcrystalline Wax |

|

|

| |

|

Refined & Semi Refined |

|

|

| |

|

|

|

| |

13. |

Reprocessed synthetic Rubber from DIH WEI CO LTD Taiwan |

|

|

| |

|

|

|

|

| |

|

|

|

| |

14. |

Plastic Additives |

|

|

| |

|

1) Impact Modifiers for LD/HD/PP/LLDPE

2) Impact Modifiers for PVC (Chlorenated Polyethelyne (CPE) Acrylics)

3) Polymer Process aids (PPA)

4) Flame retardants

5) Kresin

6) TPE/TPU/TPV (Taliwan)

|

|

|

| |

|

|

|

| |

15. |

Plastic Raw Materials

|

|

|

| |

|

1) LDPE - For Films/Extrusion/Molding

2) LLDPE - Extrusion/Molding

3) HDPE - For Extrusion /Molding

4) Polypropelyne - For Extrusion & Molding & GP Grades

5) PVC - For Footwear/Cable&Pipes & fittings

6) EVA - 18% and 28% |

|

|

| |

|

|

|

| |

16. |

Poly ISO Butylene From Shandong Hongrui Petrochemicals Ltd. Chaina

|

|

| |

|

Low Molacular weight PIB

Medium Molacular weight PIB

|

|

|

|

| |

17. |

Synthetic Rubber |

|

| |

|

1) EPDM -For Extrusion/Molding/Oil Modification as VI Improvers

2) SBR - 1502/1702

3) PBR - For Tyres/Tubes & Flaps etc

4) Chloroprene Rubber - For Adhesives/Vbelt/Extrusion/Molding application

5) FluoroElestomers - For Auutomotive/Orings/Seals

6) Eva - For Footwear applications

7) All kind of Synthetic Rubber nr.prime/offspec/pcu/scrap

8) NBR

9) HNBR

10) CSM

11) Chlorobutuyle Rubber

12)Bromo Butyle Rubber

|

|

|

| |

|

|

|

| |

18. |

Titanium Dioxide (Anatase & Rutyle) |

|

|

| |

|

|

|

|

| |

|

|

|

| |

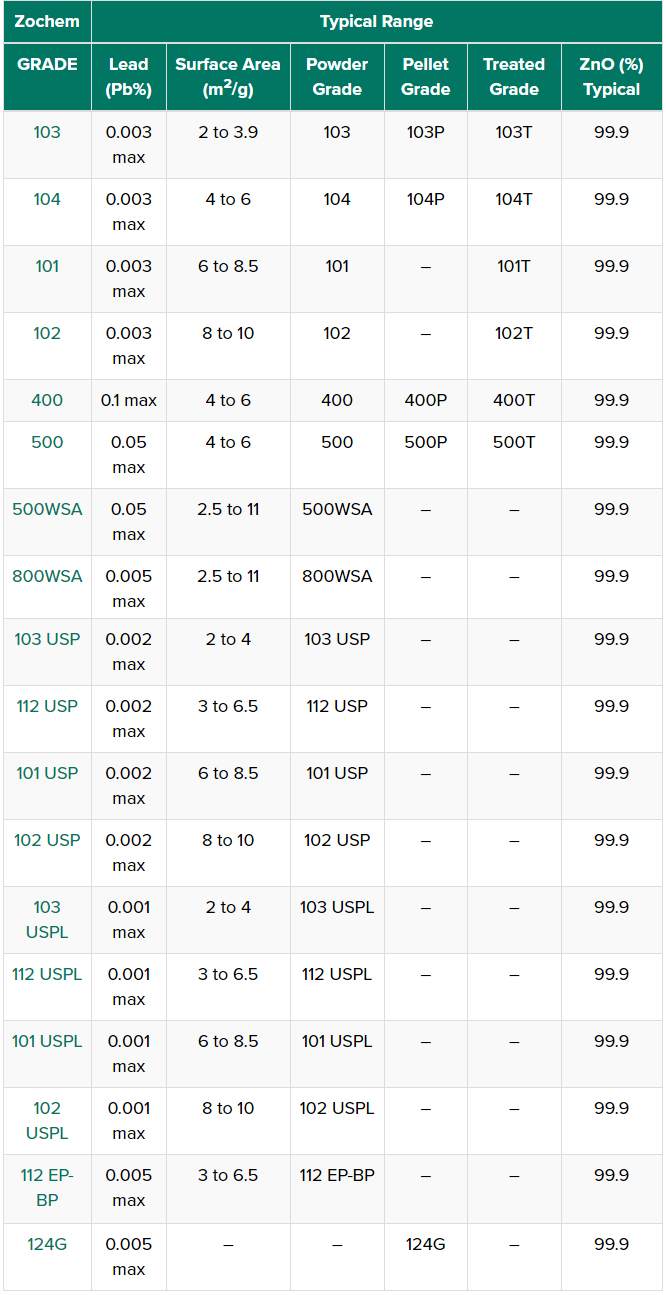

19. |

Zinc Oxide Powder |

|

|

| |

|

Priya Overseas Trades offers a variety of zinc oxide powders and pellets with purities of 99.9% and beyond, manufactured for specific market applications. Pelletized zinc oxide is an excellent option for production applications requiring high flow rates.

Based on the French Process, we start with pure metallic zinc. The metal is vaporized and oxidized in a combustion zone, utilizing our natural gas fired muffle design furnace. This typically yields consistently nodular shaped granules. Products are available with surface areas ranging from 2.7 m2/g to 10.0 m2/g. With multiple surface area options, coated and uncoated granules and purity options, Priya Overseas Trades has a product for virtually any application. Custom formulations are also available. A wide variety of packaging options are available with customized packaging as an additional choice.

Capabilities and Special Areas of Expertise:

User segments are Ceramics, Lubricants, Tires, Rubber, Plastics, Pharma, etc.

|

|

|

| |

|

|

|

| |

P. |

Nylon / Polyster Tyre codes & Industrial Fabrics - Grodno Azot (Belarus) |

|

|

| |

|

| |

Top Top |

|

|

|